Our Expertise

We can help you decide if you need highly durable, long life and controllable impressed current systems, or easy to install and maintain sacrificial anode systems.

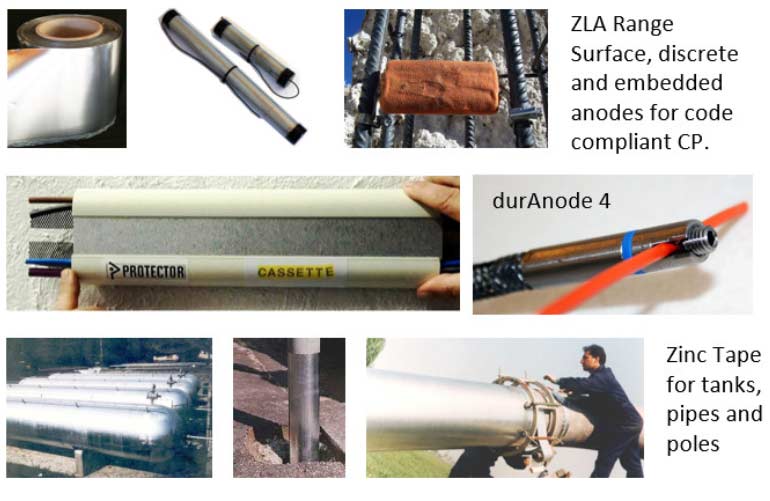

Suppliers of Cathodic Protection Amodes and Control Equipment

Sacrificial Anodes for Concrete

- Discrete and surface to protct active but not spalled areas

- For cathodic protection(i.e. remove only damaged concreter)

- That are simple and cost effective for builders and contractors

Impressed Current Anodes and Control Systems for Concrete

- Rapidly installed surface anodes for industrial applications

- New surface anodes for architectural applications

- Conductive paint systems for low weight and aesthetics

- Small diameter discrete for minimal disruption

Zinc tape – for Pipes, tanks and Steelwork Protection

- Easily replace HDG or paint systems on-site with limited prep

- Better corrosion protection than HDG

- Unique conductive adhesive and application tools.

Reinforcement Corrosion in Concrete

When corrosion of reinforcement in concrete first becomes apparent as isolated concrete cracks or spalls it is often an indication that environmental contaminants are more generally reaching the reinforcement.

If left cracking and spalling can become wide spread within a couple of years. It is important that apparent cracks and spalls are repaired and some form of protection applied to all concrete. Very often it will be too late to apply barrier coatings as the contaminants will have already penetrated the concrete. ‘Break out and patch’ is a commonly used repair method but it is often too expensive to be undertaken over all areas of contamination, and where it is it can be disturbing and create structural issues.

It has long been recognised that cathodic protection is the ideal repair method in that it can stop reinforcement corrosion without the need for breakout of contaminated concrete.

Impressed current CP is suited to major structures where the owner can afford the relatively high design, installation and maintenance cost and the deterioration must be halted over a long design life, e.g. 50 years. Sacrificial Anode CP is less expensive and requires less design and maintenance. It can be installed economically on small structures by relatively inexperienced installers but the anodes generally need to be replaced at 15-20 year intervals.

There are various impressed current and galvanic anode types available. All have their place and it is the suppliers responsibility to advise which anode type is most suited to a specific application.

Pipe, Tank and Steelwork Corrosion

Hot Dipped Galvanising (HDG) is recognised as one of the most reliable corrosion protection systems available. Unfortunately once it starts to break down it cannot be re-instated – until now. Zinc Tape can be applied to the steel surface and provides better corrosion protection than the original HDG.