CorroDisc

In concrete repair of corroding reinforcement the repairer is faced with either breaking out sound but contaminated concrete behind the reinforcement, a short lived repair or application of cathodic protection. CorroDisc is an impressed current cathodic protection anode that provides great flexibility in where to place the anodes.

With these surface anodes there is no drilling, or grooving of the concrete. The anodes are bonded to the surface, interconnected and connected to the TR unit and reinforcement. Ideal for small areas of isolated corrosion in an industrial environment. CorroDisc products are based around MMO coated titanium expanded mesh in an acid resistant mortar. Surface mounted anodes are electrochemically bound to the concrete using corrPRE’s patented paste of. Products include surface mounted discs or 400mm long strips located at 400mm centres.

Advantages

- Easy economic installation – Surface applied thanks to the ion-conductive adhesive, and therefore the most economic CP system on the market avoiding grinding, drilling or embedding the anodes in the structure.

- Natural Gas venting – The microcrystalline structure of silicates has a pore size that allows the free passage of water vapour and oxygen.

- Longevity – The insoluble silicates formed in the chemical reaction are resistant to strong acid attack and can provide for much longer life expectancies.

- Ample Protection – Satisfies the 100mV criteria for effective cathodic protection according the international standard ISO12696.

- Convenient Pilot Testing – Design engineers can easily apply and displace each individual Corrodisc anode to analyse the effects of steel polarisation in relation to anode distance, current and voltage output.

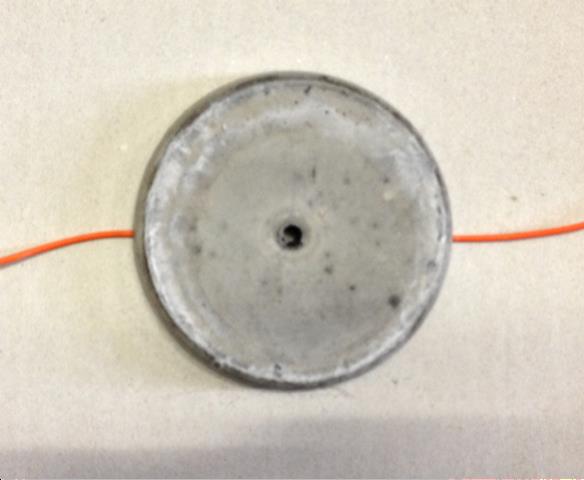

CorroDisc. A 125mm diamter MMO expanded mesh in an acid resistant mortar.

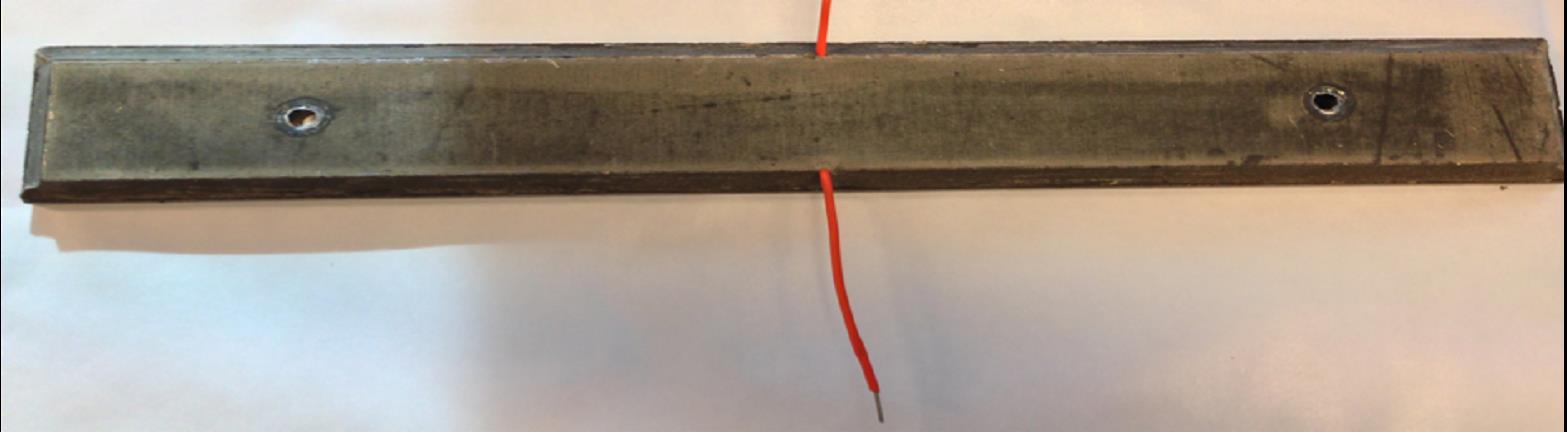

CorroDisc R. A rectangular ICCP anode for reinforced concrete.

Anode Description

CorroDisc is a range of ICCP composite anodes specifically designed for electro-chemical protection, known as impressed current cathodic protection (ICCP), for the prevention of corrosion of the concrete steel reinforcement according the international standard ISO/EN 12696.

The current required for cathodic protection is provided by a DC power source (e.g. Camur) supplied through a anode feeder cable to MMO coated titanium expanded mesh embedded in mortar. The anodes are pre-manufactured as a complete anode system. The heart of the anodes is based on a MMO-coated titanium electrode. This electrode material is pre-casted in an acid resistant cementitious mortar.

Surface mounted anodes come with ion conductive adhesive backing while internal anodes have the ion conductive paste or a mineral grout injected around them. It is important to protect the ion conductive adhesive from water as it is water soluble. For this reason the surface anodes have a bevelled edge so that a bead of sealant can be gunned around the edge of the anode. The ion-conductive paste functions as a salt bridge, bridging the mortar and concrete structure thereby avoiding electrochemical reactions taking place in the paste.

The anodic electrochemical reactions taking place on the electrode material produce hydrogen-ion (H+) and oxygen gas (O2). The acidification by the anode reaction will not harm the mortar and the oxygen gas will be easily dissipated by the natural porosity of the silicate based m.

Applications

The flexible arrangement of CorrroDiscs makes them ideal where the geometry of the surface that CP is to be applied to is complex and an impressed current system is required for longevity and control. Details of the anodes are included in the Specification table (right).

The ion conductive paste/adhesive has a peeling capacity ≥ 0.125MPa; thickness of approx. 1mm and a resistivity ≤ 1 kOhm.cm. corrPRE have 20 years history of performance on this material. The anodes are connected by Ti wire using Ti crimps. Wires are typically embedded in a grouted saw cut.

Type | 125 | R | D1 |

|---|---|---|---|

Form | Solid mortar disc with self-adhesive ionically conductive backing | Solid mortar rectangle with self-adhesive ionically conductive backing | Solid mortar narrow cylinder inserted in hole & surrounded by ZAP paste of mineral grout |

Application | Surface mounted | Surface mounted | Embedded in drilled holes |

Size | 125mm dia. x 12mm thick | 400x60x15mm thick | 120mm longx16mm diameter |

Mechanical Fixing | Central 6mm diameter plastic fitting | 6mm diameter plastic fitting at each end | None |

Weight | 250gm | 500gm | 50gm |

MMO Titanium type | Expanded mesh | Expanded mesh | Expanded mesh |

Mesh area connections | 113cm2 1mm dia. x 50mm insulated Ti wire on opposite sides | 190cm2 1mm dia. x 50mm insulated Ti wire on opposite sides | 18cm2 1mm dia. x 50mm insulated Ti wire on opposite sides |

Expected life | 100yrs at 5mA/anode 50yrs at 10mA/anode 30yrs at 16mA/anode | 100yrs at 8mA/anode 50yrs at 16mA/anode 30yrs at 26mA/anode | 100yrs at 8mA/anode 50yrs at 16mA/anode 30yrs at 26mA/anode |